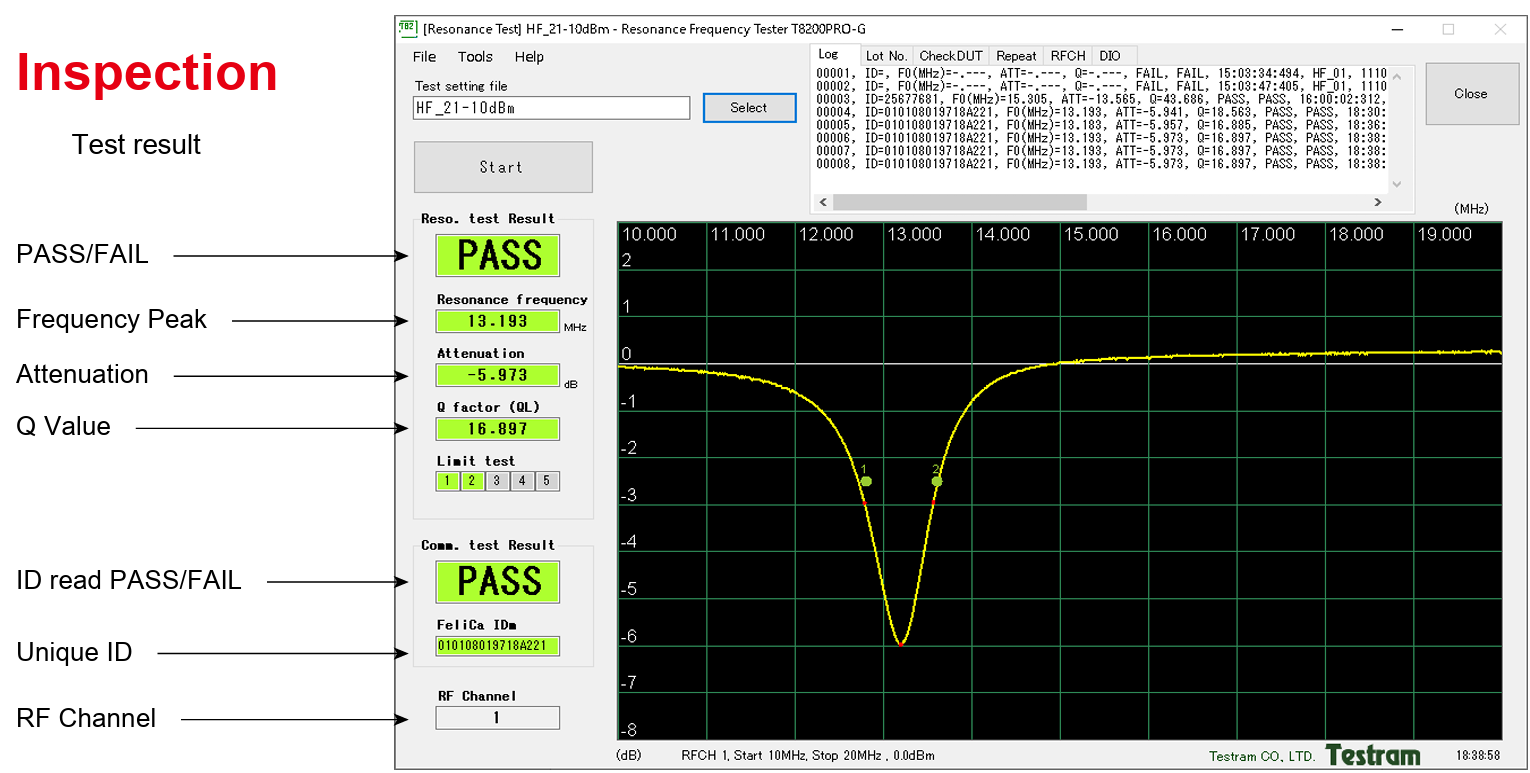

Overview

During mass production of Dual-interface/Contactless Card Inlay, Smart Card, RFID/NFC Antenna and

Transponder, all products need 100% online inspection with RF performance for better QC control.

In addition, Dual-interface Card's Inlay has more strict Frequency control before/after chip bonding due to

antenna making quality.

This multi-channel HF/NFC tester T8200Shannon, can be equipped into auto-equipment(handler) to

execute 100% RF performance inspection with Resonant Frequencies, Q Values, RF attenuation and

communication protocol. Also, collect chip UIDs and record in log file.

T8200Shannon is composed of a test host and several expansion boards. The modular design allows

multiple expansion boards to be selected according to the test target to realize synchronous detection of

multiple test targets, greatly reducing the detection time.

It's ideal testing tools during production for dual interface/contactless card, Inlay and NFC transponders

with high speed of 150msec/run.

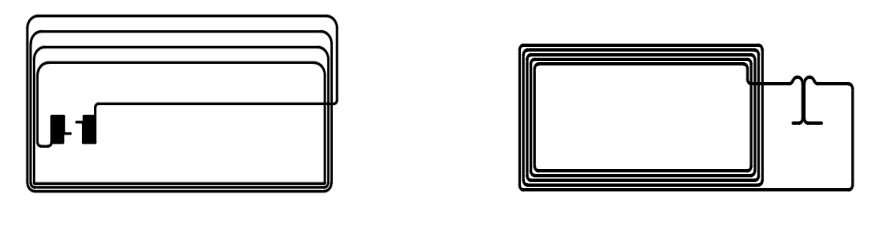

User

Ø Dual interface Inlay, card manufacturer (wire soldering, coupling, conductive epoxy or conductive tape ACF etc.)

Ø Contactless Card Inlay and NFC transponder manufacturer

Ø RFID Inlay, RFID Tag manufacturer

Ø RFID transponder machine maker (flip-chip bonder, convertor, perso and inspection)

Features

Ø High speed inspection 150ms for all targets/run

Ø Multi-function of detecting RF performance (Frequency, Q-factor, attenuation), communication protocol and UID identify for HF smart card or RFID transponder products

Ø Can measure inlay RF performance of Dual-interface card or NFC transponder before or after chip bonding

Ø Machine can work with 2~16 boards at same time, each board connected with 2 channels of the antenna, a total of 32 channels (One Pass inspection). The detection module can work independently.

Ø Tester equipped with equipment(Handler) connected to DIO interface, can be easily integrated and installed into various automation equipment.

Ø User can use external software to control the T8200Shannon to facilitate quick response of data and signals between programs.

Ø Measuring log is timely sorted and saved by index (such as production batch, date and custom name)

Measuring Principle

Ø T8200 Shannon makes PASS/FAIL judgments that performs contactless measurement of the resonance frequency, attenuation, Q-factor and nearby non-contact Smart cards and RFID tag to use magnetic field couple. Please refer to T8200PRO-G for a detailed description or contact us

Ø It measures transmission or reflection characteristics to sweep frequency and couples magnetic field between measurement probe and measurement targets (contactless Smart card, RFID tag).

Specification

Item | Parameter | Remark |

Measurement | Amplitude of the Transmission or reflection voltage |

|

Test items | Resonant frequency, attenuation, Q-factor, UID reading | (UID: option) |

ID reading protocol | ISO14443A (MIFARE Classic, MIFARE Ultralight) ISO14443B , FeliCa ISO15693(Tag it HF-I Plus/Pro, I-CODE SLIX2) | Option |

Number of probe | 2 CH/unit | <=32 probe |

No. of measure point | 100~2048 points |

|

Test time | 150msec/Cycle |

|

Test result saving | Test log file(*.csv): | Need to connect PC |

Frequency | 1MHz~100MHz |

|

Output RF Power | -30 ~ +15dBm |

|

Operation Mode | PC link mode: manual control, Digital I/O(DIO) Stand-alone mode: Digital I/O(DIO) |

|

System Requirements | OS: Win10,11, USB2.0 or higher |

|

Power supply | DC 5V±5% (current consumption less than1A) |

|

Size, Weight | 80×180×170 mm, 1.8Kg (1 host and 1 XM. Board) | XM-boards can be added |

Application

Ø Inlay production inspection of dual interface cards and contactless cards.

Ø HF/NFC tag antenna (multiple rows. Roll to Roll 100% production inspection)

Ø HF/NFC INLAY and label finished products (Multi-probe in a line. Production inspection of pitch to

pitch)

Ø For Dual-interface Antenna performance test before chip bonding

Case Sharing

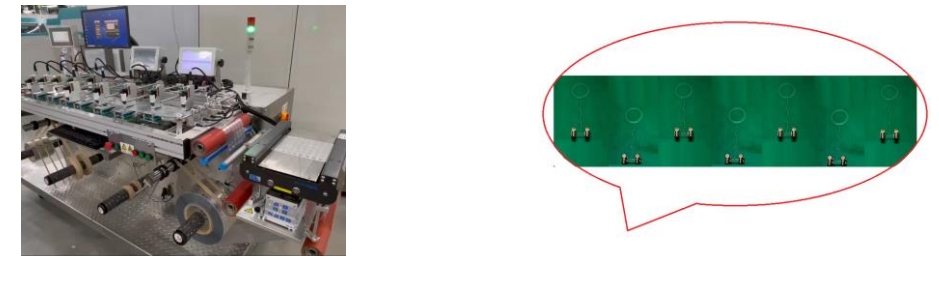

When a machine equipped with T8200 Shannon, multiple detections can be implemented simultaneously,

speeding up the overall test speed. The machine can receive testing results from T8200Shannon's various

probes, and once unqualified signal found, the mechanism will execute the N.G. marking action. If machine

has a PC installed, you can also record all test results in a log file.

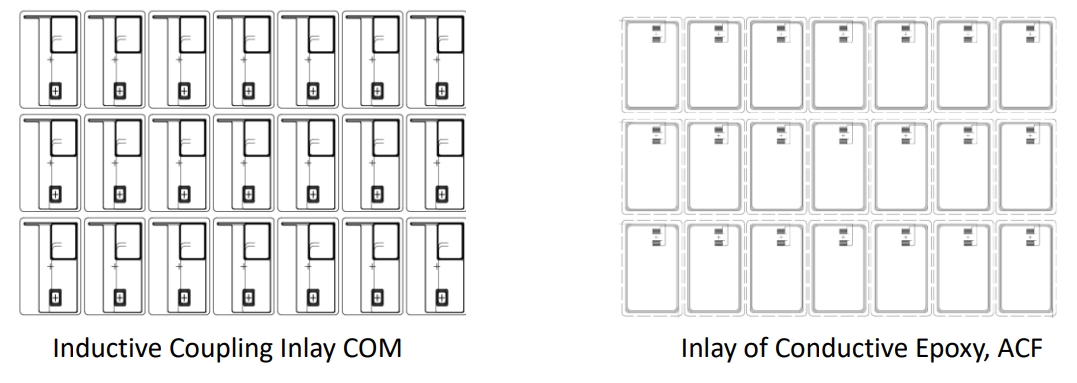

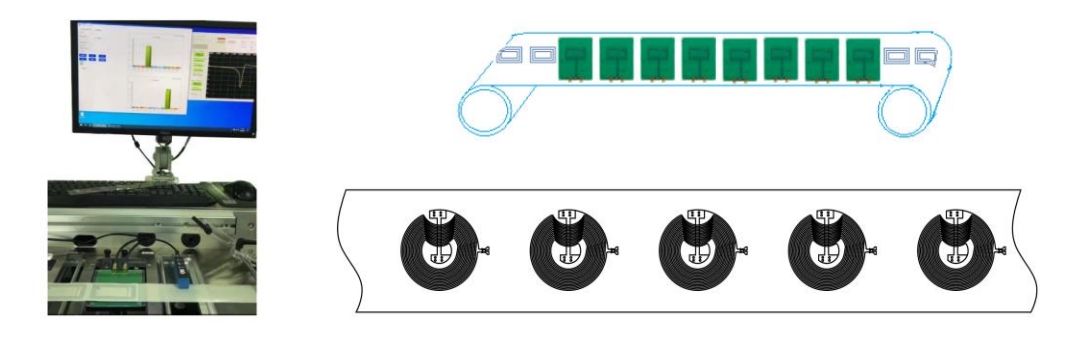

Ø Multi-probe in a line Pitch to pitch application

Ø Multi- channel step by step application

Ø Sheet Card Inlay likes layout 3x8, 5x5 or 6x8

◼ During production of HF Sheet Inlay, 100% RF inspection (Resonant Frequency, Q-factor and

Attenuation, Protocol) and UIDs capture can indicate the well QC control in different process of

embedding, welding, collecting and lamination.

◼ The machine equipped with T8200 Shannon can be custom-developed with semi-automatic or

fully automatic solution.

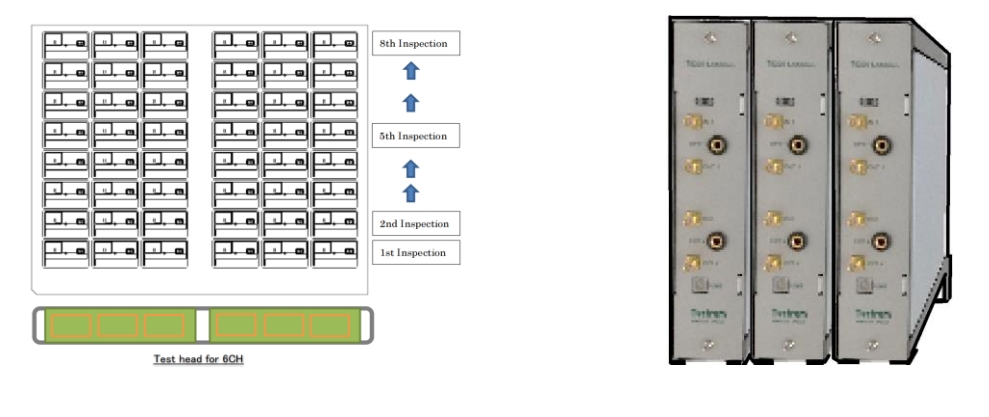

Ø Application for Coupling DI Card Inlay Inspection

The coupling antenna has no closed-circuit because of None chip physical connection. It is difficult to obtain

inlay data through ordinary reader, which brings the potential quality risk during production.

At this point, deploy T8200 Shannon into automated testing equipment (ATE handler) becomes very easy!

With Muti-channel Test Probes and customized Test Head as inlay layout, the key parameters of Inlay

Resonant Frequency, Q-factor and Attenuation can be measured even without chip connection.

Manufacturer can quickly detect defective products through multi-channel curve anomalies and data

changes, and identify them to avoid N.G. Inlays flowing to next process, so as to improve the production

rate and reduce loss.

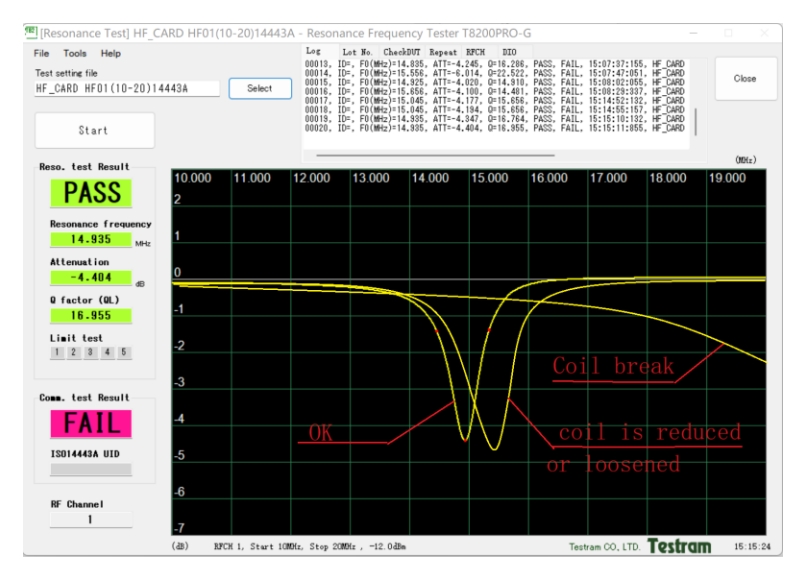

The regular defects for DI Inlays are: winding fracture, copper wire difference, buried wire damage or

loosening, substrate deformation, copper wire jumper damage, etc.

For example

The Max. Resonant Frequency of normal

transponder is about 14~15MHz.

When coil antenna turns is less or the

buried wire is loose, Max. Resonant

Frequency will be changed (become

larger).

When coil copper wire is broken,

Maximum resonant frequency offset is

obvious and reaching about 45MHz.